Projects

My design process focuses on simplicity and effectiveness, aiming to achieve the most effective and robust solutions. Below are some key examples of this approach.

Drop Test

For Stress Testing of Radomes

This fixture was designed to establish a standardized testing procedure for assessing the strength of 5G antenna radomes. It employs an electromagnet to suspend a metal ball at a specified height, along with a displacement sensor to measure the test piece's displacement upon impact. The jig incorporates built-in safety features, including a normally active magnet, minimize the risk of injury.

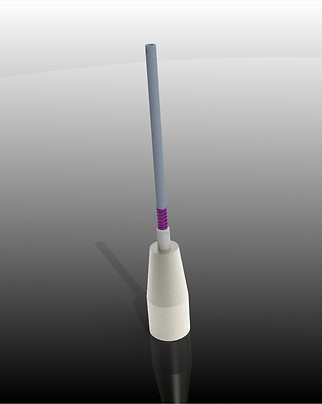

Riveting Tool

For Installing Antenna Radiator Rivets

This tool was created in order to minimize the time needed to install rivets during the assembly of Radiators for 5G antennas. The design allows multiple types of Rivets to be installed and therefore eliminating the need for extra tools.

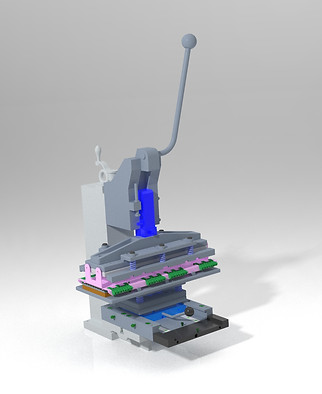

Gluing Press

For the accurate PHS gluing on Bridges

This press fixture was designed in order to achieve a precise gluing location and pressure while minimizing the cost of production. The designed spring bed allowed for precise gluing pressure without the need of an expensive pneumatic press.

Position Detection Jig

For the accurate PHS Tuning

This positioning Jig allows the antenna Tuners and Developers to have an accurate positioning feedback. With the use of a linear inductive position sensor, the user can ensure the accurate positioning of a PHS tuning arm

Soldering Stencil Jig

For use in the Wave-Solder machine

This Soldering stencil allows for easy installation and removal and it is tailored for the needs of serial production. It protects sensitive components while allowing the Wave-Solder nozzle to be positioned close to the joint.

18 Speed Transmission Integration

For Heavy Duty Natural Gas Engines

As the lead engineer for integrating an 18-speed AMT transmission into a Class 8 heavy-duty truck model lineup, I oversaw all engineering activities, testing, and DFMEA.

%20-%20Creo%20Parametric.png)

5 inch Drone Build

For acrobatic training purposes

Built around the TBS Source One V5.1 frame, this 5-inch freestyle quad is designed for freestyle flight. At its core is the SpeedyBee F405 flight controller and ESC stack, paired with T-Motor Velox V2207 motors for punchy, responsive power delivery. Video is handled by a Happymodel OVX303 VTX and RunCam Robin 3 camera.

Control is managed through a SpeedyBee Nano receiver on ELRS, and the quad is powered by an RDQ 1300mAh XT60 battery. Topped off with Gemfan Hurricane 51433-3 tri-blade props, this build strikes a great balance between efficiency and raw freestyle performance.

Automated Grow Box Control System

For seedling starters and small fruiting plants

This project is a fully automated grow environment controller built around an ESP32 microcontroller. The system reads environmental data from an AHT20+BMP280 combo sensor for temperature, humidity, and atmospheric pressure, as well as a capacitive soil moisture sensor to monitor watering needs. Based on this data, the ESP32 drives four relays controlling an intake fan, water pump, humidifier, and heat mat, keeping the grow environment consistently dialed in.

Humidity is regulated using a PID controller implemented in software, allowing for precise, responsive control rather than simple on/off switching. The system also features a web-based dashboard accessible over WiFi, where live sensor data can be monitored and PID tuning variables can be adjusted on the fly. Individual relays can also be manually forced on through the dashboard for testing and maintenance. Software-level failsafes and lockouts are in place to protect both the plants and the hardware from unsafe operating conditions.

Guitar & Bass Rewiring and Electronics Upgrades

What started out of necessity has turned into a genuine skill set. Unable to afford high-end instruments early on, the solution was simple: buy cheap and upgrade smart.

Through hands-on experimentation with replica Fender basses, this meant swapping out stock pickups for Seymour Duncan pickups and replacing inferior components with quality hardware like CTS pots and premium wiring.

The results speak for themselves. A bass originally purchased for $80 now outperforms instruments costing over $1,000 (in frequency response, tone and subjective sound), all for a total parts investment of under $300.